Montrac Transport System

Intralogistics

Getting products, workpieces and materials swiftly and directly from A to B. In other words: the perfect internal transportation

Integrated Automation

Reliably and economically to their destination: In the smallest of spaces, montrac® becomes part of the assembly and incorporates the workpieces directly into the assembly process.

Process Sequence

Intelligent process stations from montrac®: From the linking of individual process steps and assembly areas right up to the automation of the entire production.

-

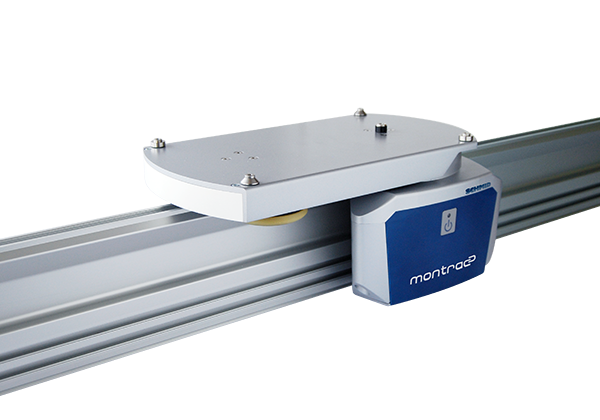

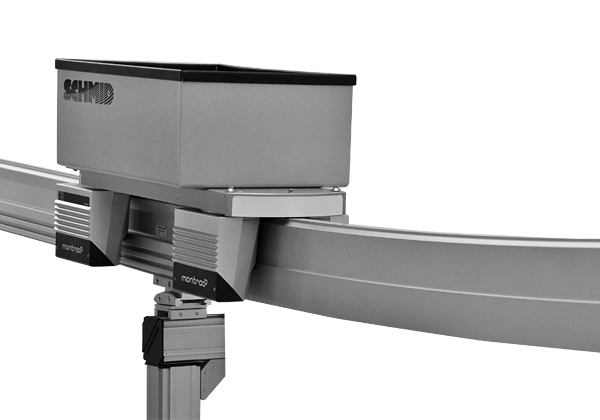

Basic Shuttle G4

The shuttles are the intelligent material handling vehicles and the centerpiece of every montrac® system. A shuttle is available with one drive axis or as a twin-axle shuttle. Each shuttle has a sensor, which prevents potential collisions with obstacles or other shuttles.

-

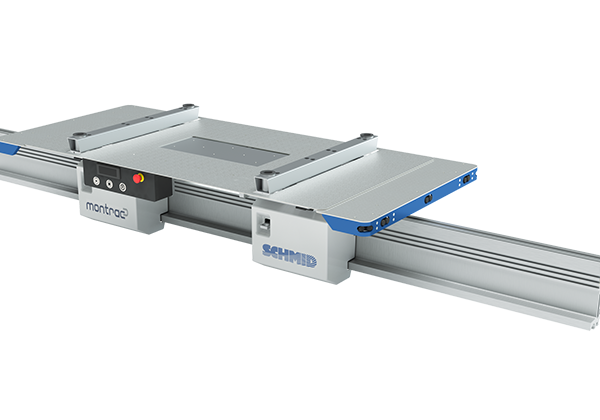

The Industrial Shuttle 200

is a revolution for the intralogistics market up to 200 kg. With its speed of 20 m/min it is up to four times faster than transport systems so far available on the market. Waiting times due to loading or downtimes as with free-running AGV (automated guided vehicle systems) can be omitted

-

The SupoTrac

The SupoTrac serves as a support for manual workstations. The shuttle platform is slightly lifted up from the Shuttle; thus processing tasks are possible without straining the Shuttle and Trac with force impact.

-

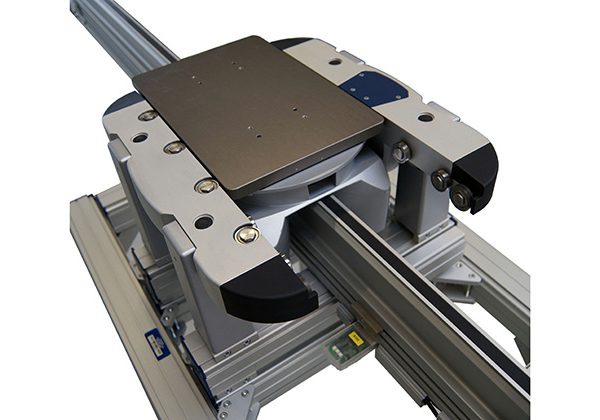

PositioningUnit PU-4

A PositioningUnit is used when the shuttle is to be precisely positioned and / or when the workpiece platform must be additionally supported during the machining operation. The PositioningUnit is available for single and multiple positioning

-

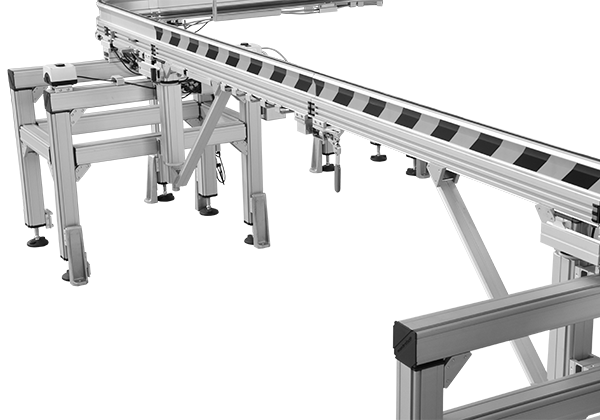

FlexTrac

Heignt differences can be overcome by FlexTrac, e.g. between machines and processing stations, without using a lift. Depending on the application different ascent angles up to 12° are possible.

-

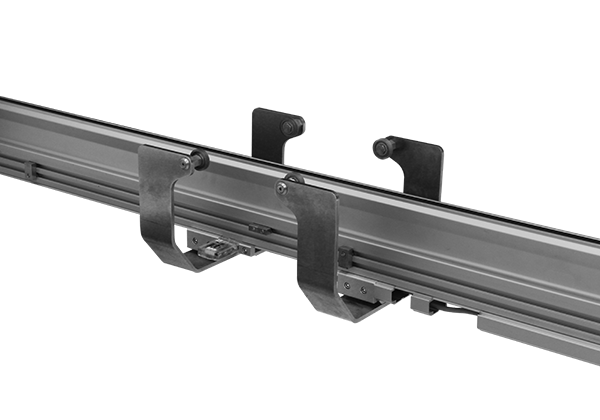

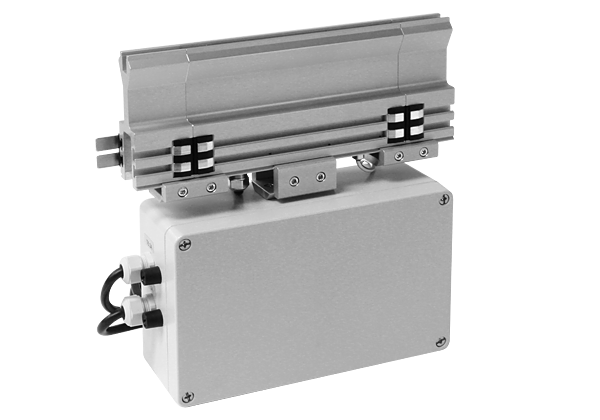

Isolation Trac

For larger plants with many shuttles two or more supply units are used. IsolationsTracs decouple the individual sections from one another to avoid any shortcircuit.

-

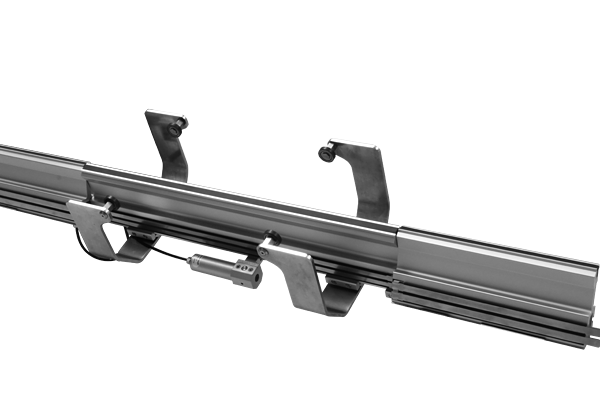

TracDoor

The TracDoor (gate) allows passage through a montrac® line or access to manual works stations within the line. The principle of a TracDoor is very simple: The gate is attached to a pivot point and can be opened manually.

-

ErgoTrac

With the ErgoTrac a manual workstation can be set up more ergonomically. The workpiece platform is tilted 25° towards the operator. This makes the platfomr ergonomically more easily accessible and improves the visibility.

-

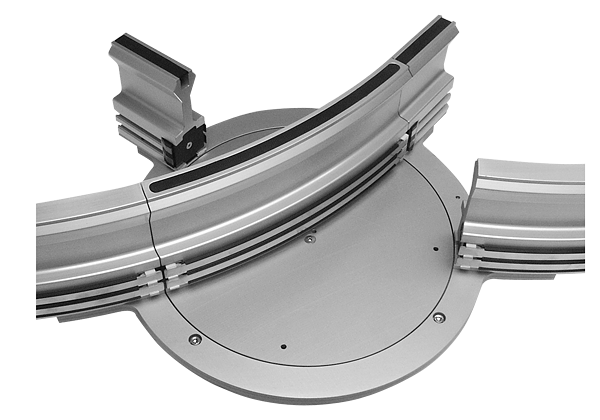

TracCrossing

The crossing makes it possible for two lanes to intersect each other at a right angle. The electrical power is supplied directly from the conductor rails.

-

TracSwitch Arena

The TracSwitch Arena serves to convey the Shuttles either from one lane to a bypass (45°-output) or to the main lane. Thus it is possible to perform a complete bypass with a single component.

-

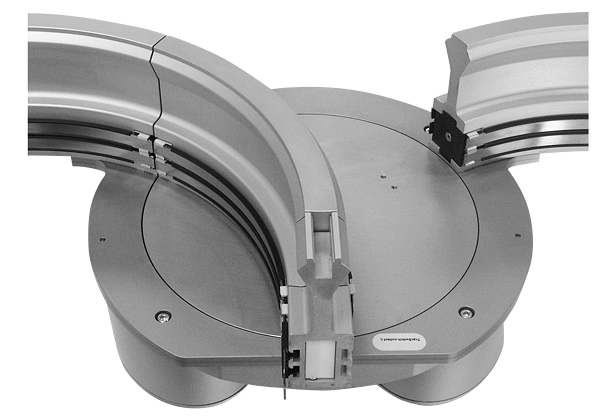

TracSwitch

The track switch is used to distribute Shuttles from one lane to two, and vice versa. Thanks to the small radii, bypasses and branches can be implemented in narrow spaces. The TracSwitch is operated electrically and is powered directly from the conductor rails.