Palletising

Palletising

Layer forming systems

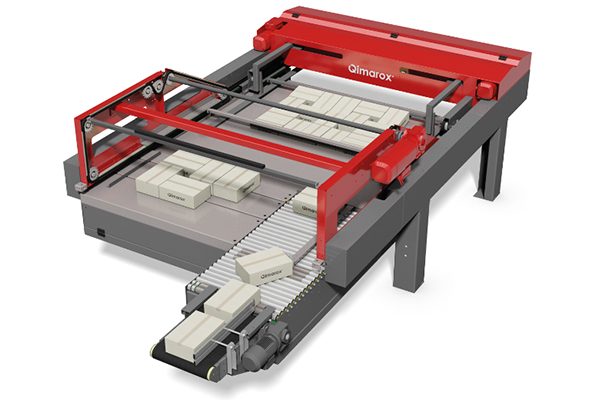

Qimarox offers a wide range of palletisers that all have one thing in common: the unique way in which layers are formed. For the first time, the great flexibility of robotic palletisers has been combined with the high capacity of layer palletisers. Qimarox pattern-formation conveyors have even been patented. Whatever the palletiser module, the secret of all Qimarox’s palletisers lies in their pattern-formation sliders. The supplied products are pushed together with the pattern-formation slider until a row or layer has been formed of the correct pattern.

Crossrunners

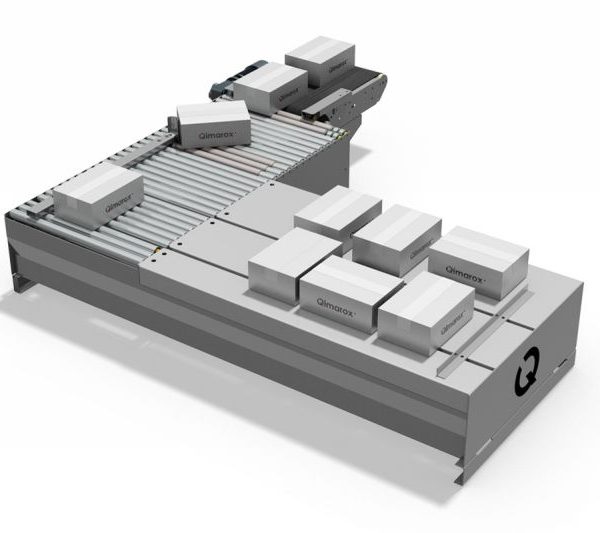

Qimarox Crossrunners are an ideal solution for in-line placing of multiple palletisers. Thanks to the unique design, a single roller conveyor is sufficient to feed pallets in and out for multiple machines operating in machines. The products are supplied by means of a feed belt that is placed on left or right side of the formation location. To do so the machine has a built-in buffer, where each formed row remains until a layer is complete. By depositing an entire layer at a time, the Highrunner mk7 needs to make fewer movements. This saves time, increasing the capacity when compared to other palletising systems.

Highrunner mk7

What distinguishes Highrunners from most other palletising systems is the position of the pattern-formation conveyor. In the Highrunners, the pattern-formation conveyor is located at a height, while the pallet is moved up and down with a pallet lifter. The top of the pallet is consequently always located at the same level as the pattern-formation conveyor

-

Brochure

BrochureHighrunner mk7

What distinguishes Highrunners from most other palletising systems is the position of the pattern-formation conveyor. In the Highrunners, the pattern-formation conveyor is located at a height, while the pallet is moved up and down with a pallet lifter. The top of the pallet is consequently always located at the same level as the pattern-formation conveyor

-

Brochure

BrochureCrossrunners

Qimarox Crossrunners are an ideal solution for in-line placing of multiple palletisers. Thanks to the unique design, a single roller conveyor is sufficient to feed pallets in and out for multiple machines operating in machines. The products are supplied by means of a feed belt that is placed on left or right side of the formation location. To do so the machine has a built-in buffer, where each formed row remains until a layer is complete. By depositing an entire layer at a time, the Highrunner mk7 needs to make fewer movements. This saves time, increasing the capacity when compared to other palletising systems.

-

Layer forming systems

Qimarox offers a wide range of palletisers that all have one thing in common: the unique way in which layers are formed. For the first time, the great flexibility of robotic palletisers has been combined with the high capacity of layer palletisers. Qimarox pattern-formation conveyors have even been patented. Whatever the palletiser module, the secret of all Qimarox’s palletisers lies in their pattern-formation sliders. The supplied products are pushed together with the pattern-formation slider until a row or layer has been formed of the correct pattern.