Spiral Conveyors

Spiral Conveyors

Used in a wide range of markets and applications for vertical transportation, temporary storage and the accumulation of single goods and packed products.

The SpiralVeyor® SVe

The SpiralVeyor® SVe Series are the extreme wide belt spiral conveyors in the AmbaFlex SpiralVeyor® program and specially designed to handle oversized goods and bulk flow. The wide belt is built up from multiple parallel tracks that form one conveyor belt. The multiple belt track arrangement ensures enhanced pull strength for high load applications. Many other options are also available to customize / configure this spiral conveyor for specific applications and functions.

-

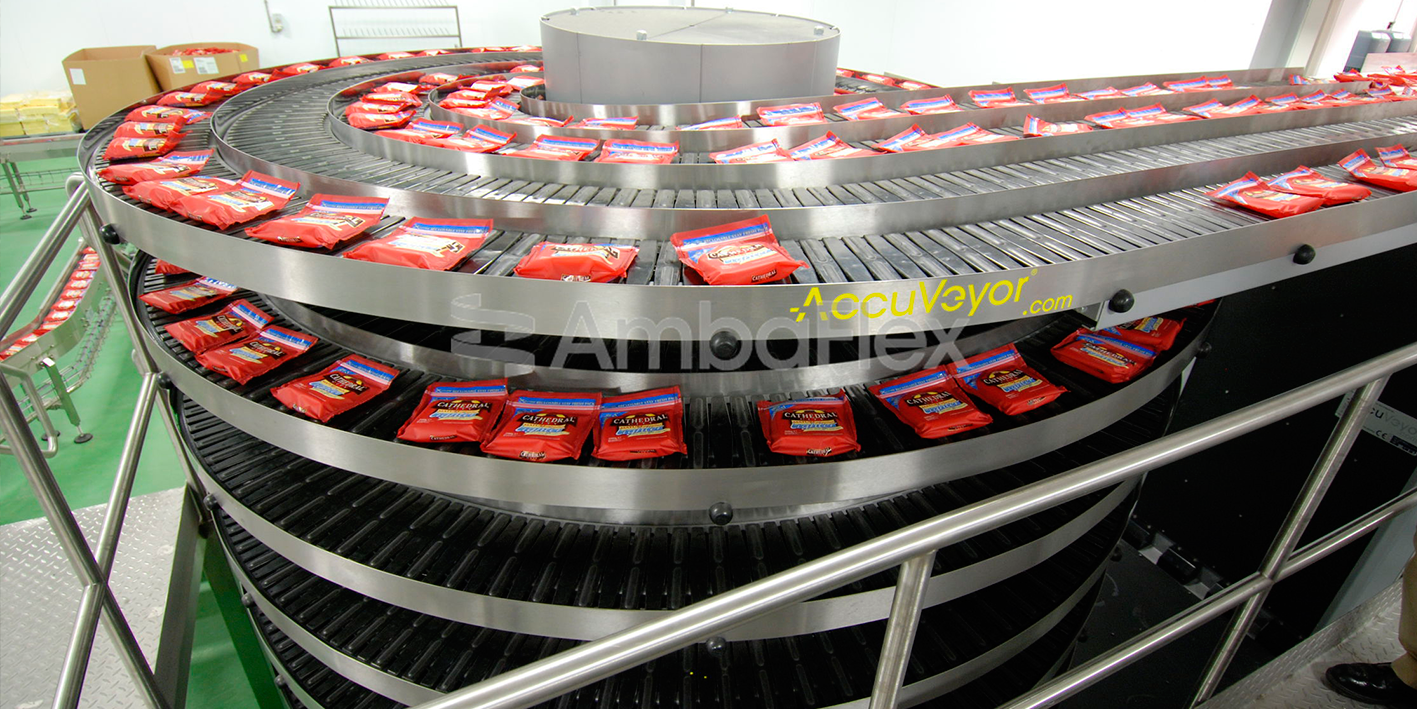

SpiralVeyor® SV Series

The SpiralVeyor® SV Series is a general purpose spiral conveyor that is applied in many industries and across a wide range of applications. Within the AmbaFlex SpiralVeyor® program, these are the midrange in belt width. They can be fitted with one or more parallel individual driven conveyor tracks arranged parallel to each other. The SlimLine version is designed to save valuable floor space and defends the title of World’s most compact spiral elevator. Furthermore, many other options are available to customize / configure this spiral conveyor for specific applications and functions.

-

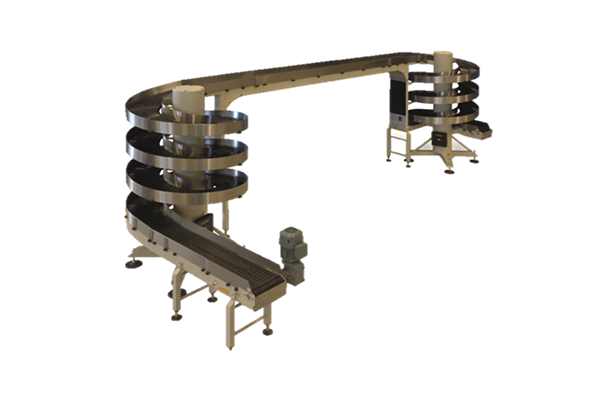

Portal Concept

The SpiralVeyor® ML is a Multi-level Spiral elevation solution with patents pending. In the 1990s the AmbaFlex SpiralVeyor® became an industry standard for vertical movement from a single infeed to single discharge, lifting or lowering. The ML version is an improvement on the classic SpiralVeyor® concept adding extra infeeds and discharges. The SpiralVeyor® ML is most applied in pick modules, order release systems and goods to man concepts.

-

The multitrack SpiralVeyor

The multitrack SpiralVeyor® concepts offer a maximum of compactness and flexibility in spiral conveying. The multitrack solutions apply to both elevation and accumulation uses. Off-the-shelf multitrack products are available for the SpiralVeyor®’s featuring the X-functionality or any specials via the engineered products program. In fact, any configuration that is technically possible can be made for applications ranging from primary packed items such as liquid filled containers / bottles up to secondary packed items, as well as totes.