Warehouse Technology

Warehouse Technology

Many materials handling activities involve strenuous or repetitive activities, such as lifting loads, installing a component, or picking products into totes. Ergonomic equipment is used in many facilities to help the task fit the worker, instead of forcing the worker to fit the task.Those physical stresses could lead to worker injury and additional costs associated with lost productivity and downtime.

-

GEBHARDT CHEETAH Miniload – Type 701

For storage and retrieval machines acceleration, speed and delivery time take more and more on greater significance. For this, GEBHARDT is setting new standards. “Who is faster?” That was the target of the GEBHARDT engineers in developing the new miniload type “CHEETAH®”. “CHEETAH®” – as the name implies – is extremely fast and very lightweight thanks to innovative materials. The Cheetah storage and retrieval machine (ASRS) with its innovative construction approach represents dynamics and efficiency in automatic small-parts storage. The Cheetah ASRS is constructed of various materials, intigrating cutting edge fibre-composites. The bonded framework structure has been comprehensively tested for the stress and service life of a small parts ASRS crane. The rigid framework structure allows for shorter stabilisation times during operation.

-

The StoreBiter 300 MLS

(Multi-Level-Shuttle) is a highly dynamic shuttle system to serve several storage levels. In a multitude of applications, this shuttle system offers effective access to incoming and outgoing goods according to the «goods to man» principle.

The various load handling devices allow the StoreBiter 300 MLS to handle totes, cartons and trays of up to 50 kg in single or multiple depths and of varying sizes.

-

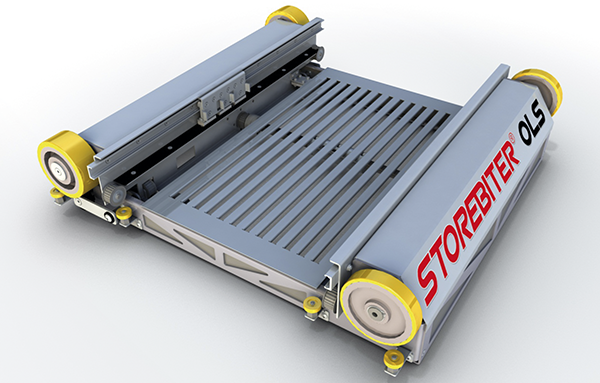

The StoreBiter 300 OLS

Is a shuttle system for the highest performance requirements. Through to various load carrying devices the StoreBiter® 300 OLS ist highly flexible in the single- or multi-deep storage of containers, trays and cartons of various sizes. The shuttle system is ideal for the implementation of the «goods to man» principle, especially when combined with the GEBHARDT SimplePick picking stations.