Bar Code & RFID

Specialized equipment and supplies represent significant investments for manufacturing and materials handling businesses. These assets are also often spread across multiple locations. Barcoding and RFID offers the ability to track these assets, which can save much time and money.

Bar Code

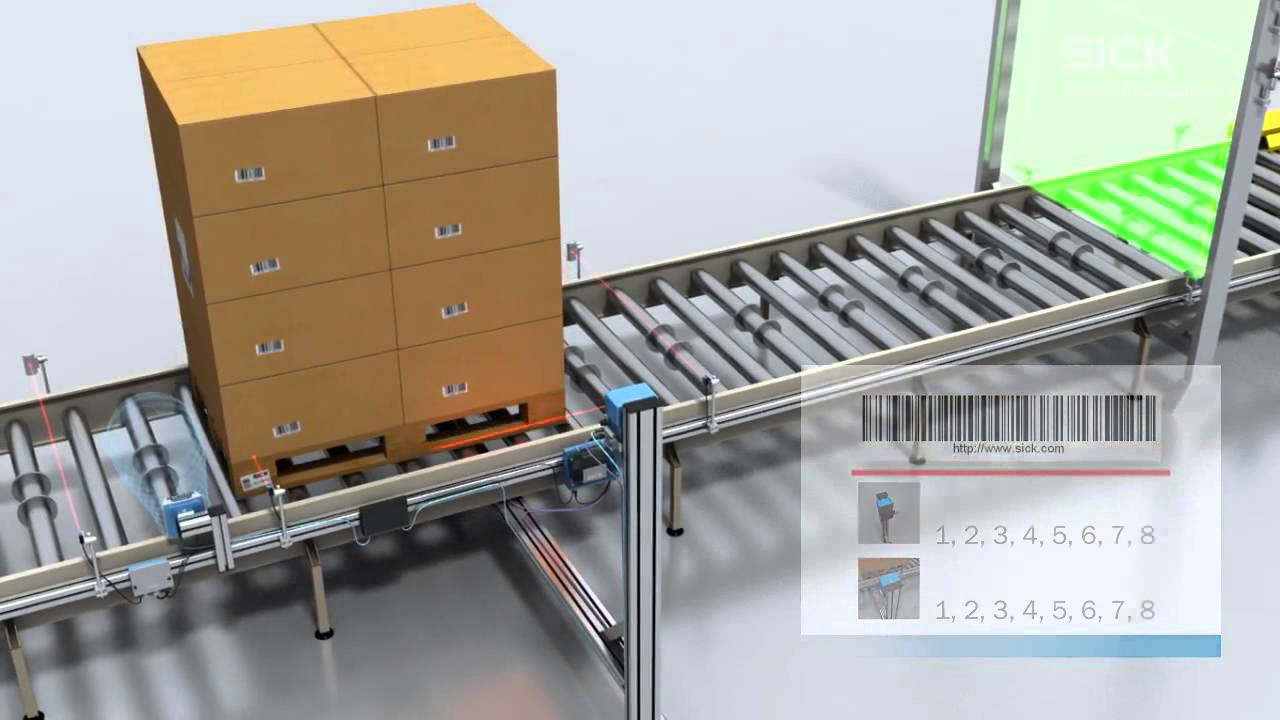

The ease of using a barcode scanner makes it an appealing alternative to traditional paper-and-pencil processing. Not only do barcodes streamline processing time, but they also enable tracking individual items within a shipment. Using barcodes can save time in several materials handling situations.

Inventories of in-house materials and equipment: While a traditional warehouse inventory may take several employees days to complete, handheld barcode scanners mean the same inventory can be completed in a fraction of the time.

The unique needs of the manufacturing and materials handling sectors are best met with a comprehensive barcode tracking system. Due to the sheer quantity of materials, supplies, and machinery used in these industries, barcodes offer a particularly beneficial solution. Not only do barcodes help reduce time spent on common activities like inventories and shipping, but they also improve revenue.

RFID

Unlike barcodes, RFID tags rely on radio waves rather than light to communicate their information. That means line-of-sight is not required and many RFID tags can be read at the same time. RFID tags can also be read through many different materials, including cardboard and most plastics. Typically in warehousing applications the RFID Tag is applied to a Carton, Tote, Box, or Pallet. The RFID Tag can be linked to both a single item or an item set within the Carton, Tote, Box, or Pallet.

One such solution took advantage of RFID tags to identify materials in a cold storage situation where barcodes could be covered by frost and rendered unreadable. The tags were combined with an AS/RS system to provide a completely automated, fast and accurate picking and storage solution.

Most all RFID tags contain at least two parts. The first is an integrated circuit for storing and processing information, modulating and demodulating a radio-frequency (RF) signal, and could possibly perform other specialized functions. The second is an antenna for receiving and transmitting the signal. More advanced tags can have sensors and batteries attached to enhance their functionality and read range.

To read the tags, RFID readers use one or multiple antennas to emit radio signals that prompt all of the RFID tags within range to respond with their unique IDs in rapid sequence. The reader then passes this information on to be looked up in a local database to determine the product’s identity. In many cases the unique ID stored on the tag is an Electronic Product Code (EPC). EPC numbers are passed to the EPC network which, in turn, will identify the product manufacturer, product type (SKU), and can provide updated tracking information.